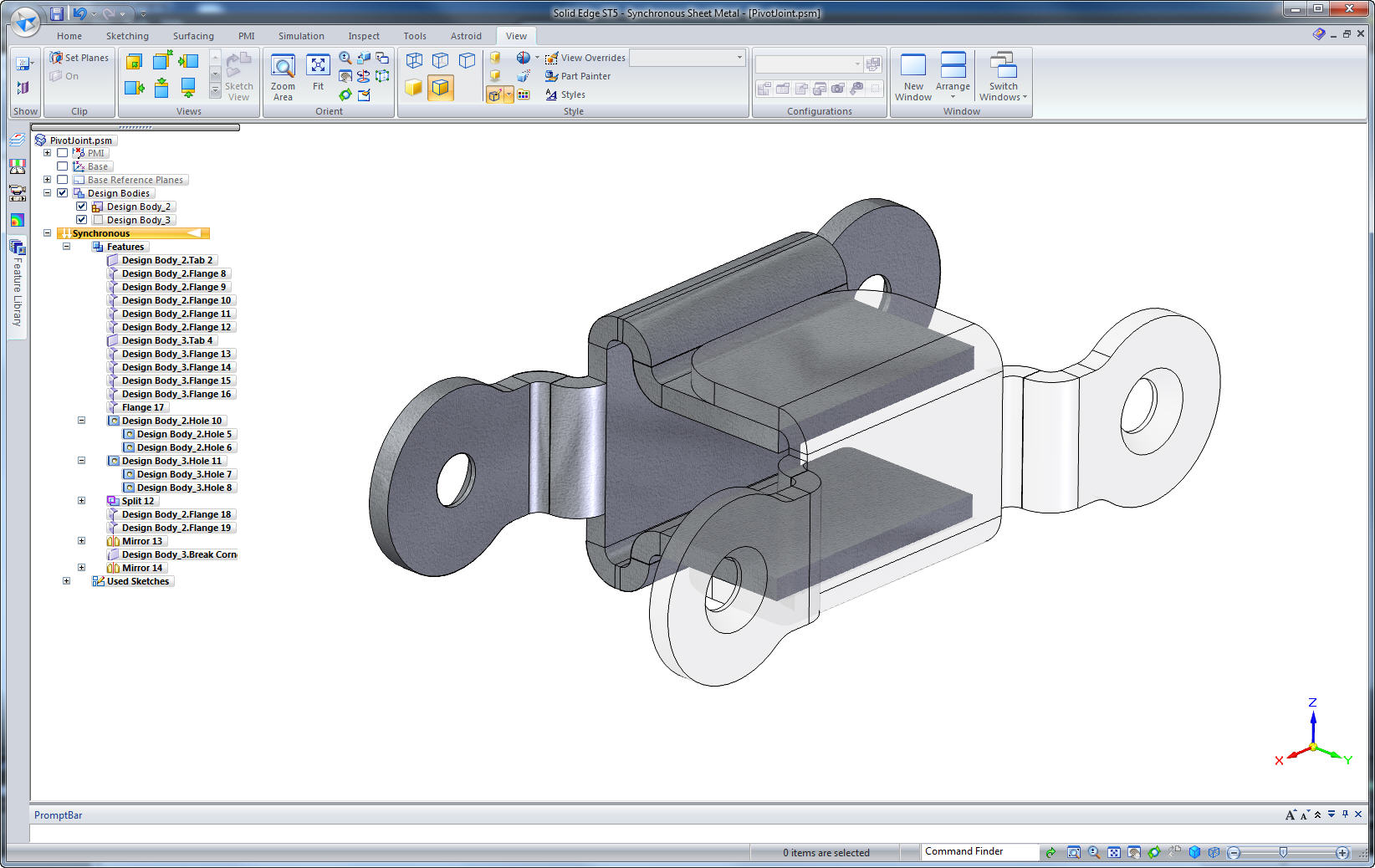

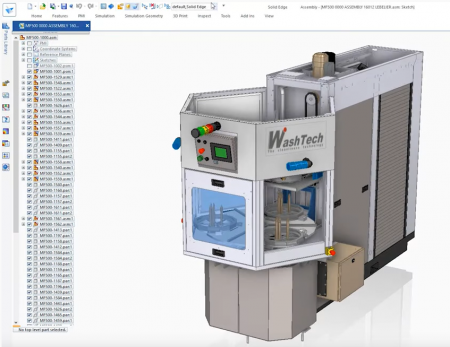

“Everyone who does this type of work has some type of solid modeling software,” he explains. When it comes to satisfying existing customers and impressing prospects, solid modeling only goes so far, according to Hare. We expect that number to increase as the company gets farther along the learning curve.” PLM is the differentiator By doing small design tests through parallel work in synchronous technology and traditional modeling, we have seen as much as a 30 percent reduction in the design phase. “By allowing us to bring in and work on data from any CAD system, Solid Edge with synchronous technology will save us the time it takes to redraw that geometry. “When we design testing machinery, we need to use the customer’s assembly data no matter what system it was designed in,” he says. Hare expects to save even more time as ICA increases its use of the synchronous technology capability of Solid Edge. This has been important in meeting customers’ requirements for ever-faster delivery. Using Solid Edge has also helped the company reduce by 33 percent the time it takes to complete a job. “Now it’s only two percent.” That represents a significant cost savings, which is particularly important now, during difficult economic times. “Prior to Solid Edge, our remanufacturing rate was 20 percent,” Hare says. Using Solid Edge to increase the accuracy of machine designs has reduced the amount of rework the company performs. The use of Solid Edge has improved operations at ICA in a number of ways. “In addition, the Solid Edge draft environment is far superior to SolidWorks.” “Inventor couldn’t do it, SolidWorks never completed it, but Solid Edge did and was the clear winner,” explains Hare. Each program was timed in the creation of a 10-part assembly.

#Does siemens teamcenter convert solid edge to solidworks software

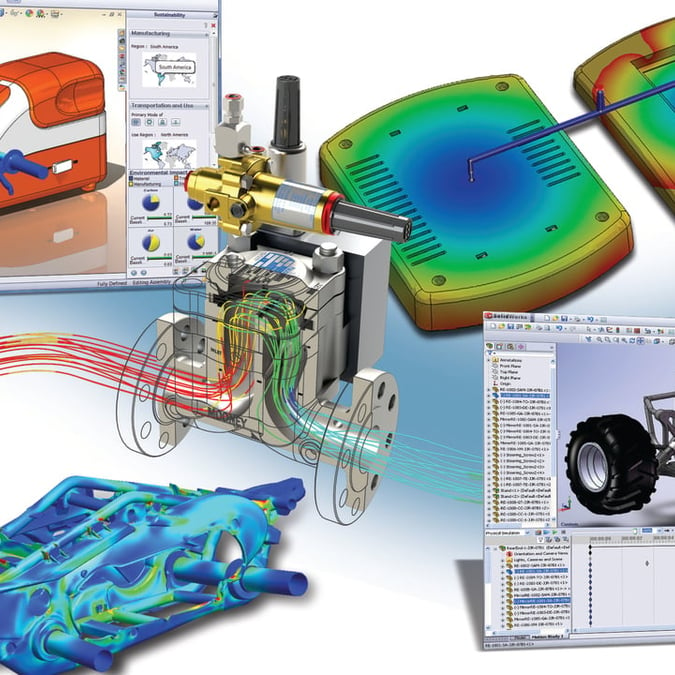

The company chose Solid Edge following a three-way trial that also included SolidWorks® software and Inventor® software. ICA has been using Solid Edge for nearly 10 years. “It inspires confidence right from the start.” Solid modeling is a start “When prospective customers come here to visit, particularly if they’re from large companies, they are surprised to see that we have the same type of technology they’re using,” says Hare. Both solutions are from Siemens Digital Industries Software. ICA’s PLM system is based on Solid Edge® software for accelerated design and Teamcenter® software (preconfigured for rapid development and fast return on investment) for a single source of collaborative decision support. Hare notes that a key element of the large-company image is product lifecycle management (PLM) technology. It also helps that while we may be small in size, we present a large-company image.”

When asked how such a lean operation can win orders from companies such as Magna, Voight Aircraft, Citation, Cooper Tire & Rubber Co., DuPont Chemical, Procter & Gamble Paper Products and Tyson Foods, ICA’s CEO Brian Hare responds, “In part, it’s because we have some top-notch machine and systems designers. ICA is an eight-person shop that competes successfully in a tight market against much larger organizations. Its services include engineering, design, construction and start-up support.

The company provides custom-fabricated machinery and control panels, complete electrical/mechanical installation and turnkey integration, custom robotics, motion applications, machine modifications and enhancements, and nondestructive testing systems for companies in a wide range of industries. (ICA) is a systems integrator and machine builder specializing in programmable logic control (PLC) system machines.

0 kommentar(er)

0 kommentar(er)